LED Control System & LED Display Screen Solution Provider - Shenzhen Linsn LED Co.,Ltd.

Telephone:+86-755-3292-5789

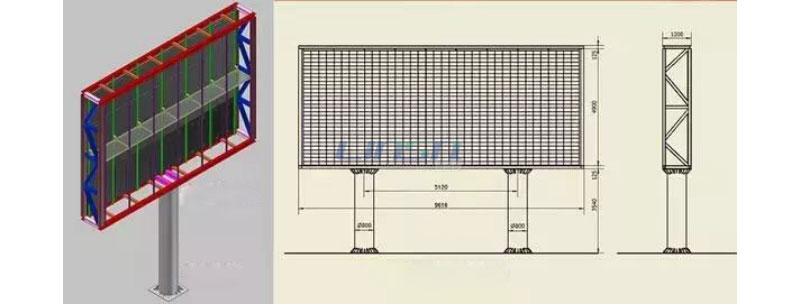

The installation of steel structure of led display screen is a complex and comprehensive technology with many contents and a wide range .The following solutions are combined with some steel structure projects to elaborate the basic principles and applicable conditions of steel structure hoisting scheme design, and summarize the feasibility of conventional installation methods and corresponding technical measures and waterproof treatment are summarized.

Due to market reasons, steel structure installation accidents and violation of regulations occur from time to time, In order to avoid unnecessary economic loss and social impact ,steel structure construction should not only strengthen the construction site management, but also in the construction organization design, scheme, technical measures and other aspects of the study and summary,according to the characteristics of the project, choose advanced, reliable and economical construction plan.

1, Policy: based on the drawings and standards, strictly implement the relevant national production safety regulations.

2, reliability: adhere to safety first, ensure the feasibility of the implementation of the plan, increase its reliability.No matter which method is adopted, the first thing to consider is whether the scheme has a successful precedent and supporting equipment, otherwise the scheme must be demonstrated.According to the characteristics of the structure, it is proved that the stability of the structure, the stress and deformation of the members meet the requirements.Whether the mechanical equipment used can meet the installation requirements.Whether the conditions of the construction site are satisfied, such as whether the civil construction environment and surrounding structures restrict the implementation of the plan, etc.

3, Economy: a good installation scheme should be simple in method, appropriate in measure, high in efficiency, low in construction cost, wide in application, and can stand the examination and test.Therefore, we must adhere to the principle of program comparison, carry out technical and economic analysis, and choose the program with short duration and low cost.

Due to the non-unity of architectural modeling and structural form, the construction site conditions vary greatly, it can be said that there is no one construction method or program suitable for any steel structure project installation, so each installation method has its own support conditions.

1.The commonly used installation methods of grid structure are: high altitude bulk method, strip and block installation method, structure slip method, support frame slip method, integral hoisting method, integral hoisting method, etc.

According to the process method:

Understand the structure form, structure weight, installation height, span and other characteristics, and try to choose mature and advanced installation technology according to the actual situation on site.

2, according to the lifting equipment consideration:

First choose their own equipment, or hire nearby.General situation: when the number of components is small, choose more truck crane;Portal rigid frame hoisting mostly choose medium and small truck crane;When the installation period is longer, the installation height and the turning radius are larger, the crawler crane is more economical than the truck crane.Overall hoisting and sliding mostly adopt hydraulic synchronous lifting (push) device;Tower crane is usually used for middle and high rise steel structure installation.

3, the overall lifting method: computer synchronous control, hydraulic lifting equipment, the process has gradually replaced the heart through mobile lifting and jack jacking scheme, the equipment is light, advanced technology.

Its applicable conditions are as follows: 1.Second, the installation height is higher;Third, the component is heavy;Fourth, limited to vertical hoisting, not horizontal displacement.That is, the higher the installation height, the heavier the lifting weight, the better the effect.

4: Ordinary hoisting: the earthwork hoisting is the use of single-angle bar, herringbone, rolling machine, pulley block and other lifting equipment for structural hoisting, which is suitable for projects with heavy components, less quantity and higher installation height.As a result of large tonnage hoisting equipment and advanced installation technology more and more, so the ordinary hoisting is also less and less.

5: The overall lifting method: it is basically similar to the overall lifting method, but different lifting equipment, suitable for small and medium-sized structure installation.Early use of multiple independent foot bar or herringbone, hoist, pulley block and cable wind system for large tonnage hoisting.Now, because of the large tonnage of cranes more, according to the needs of small and medium-sized projects to choose a number of cranes to carry out the installation.

Outdoor use of LED displays will face many challenges.wind, rain and other adverse weather, should do a good job of protection to ensure the safety of the screen operation.A good sealing installation can help reduce the risk of water inflow on the display screen, regularly clean the dust attached to the inside and outside of the led display screen, and also help the display screen to better heat dissipation and reduce the adhesion of water vapor.

1: backplate and sealant

outdoor led display needs to add a backboard and sealant, otherwise a long time, electronic components will be water,LED display will have a variety of problems.Once water enters the line, it will cause the line to burn down. these problems can be effectively avoided by using backplane sealant

2: leakage mouth

If the LED electronic display and the back board closely together, the bottom must hit the leakage mouth;The so-called leak is used to leak.No matter how tightly combined LED display front and back, after years of, there is still more or less water, if there is no leaking hole under the mouth, water will pile up over time, if the leaking hole, water outflow, so can have very good waterproof effect, to extend the service life of LED display is also good.

3: Proper wiring

Install the LED electronic display, must choose the right wire, plug wiring usually abide by the principle of larger but can not be small, namely good LED display the total number of watts, select a little bit big wire, it is best not to choose just the right or the wire is too small, so it is easy to cause line burned, which affects the safe running of the LED display.

In addition, if water enters the display screen by accident, the power must be cut off immediately and professional technicians should be sent to the scene for emergency repair.Daily waterproofing, for seepage threat to timely treatment.

Contact:LINSN LED

Phone:+86-137-8705-0055

E-mail:sales@linsnled.com

Company:Shenzhen Linsn LED Co.,Ltd.

Add:Building 11,SanLian Industry Park,SongBai Road,BaoAn District,Shenzhen,China.